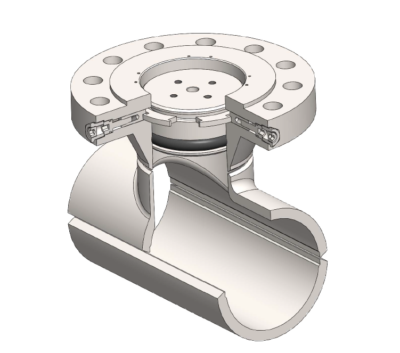

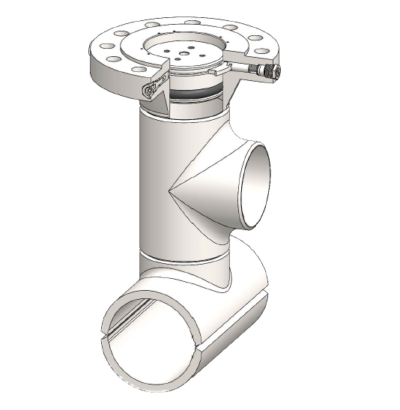

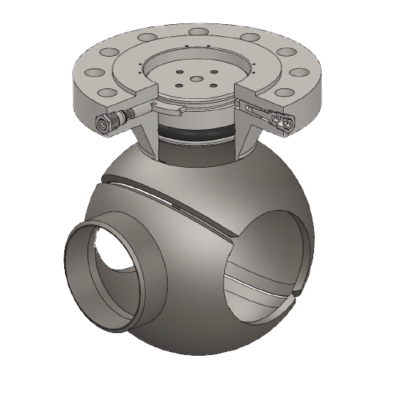

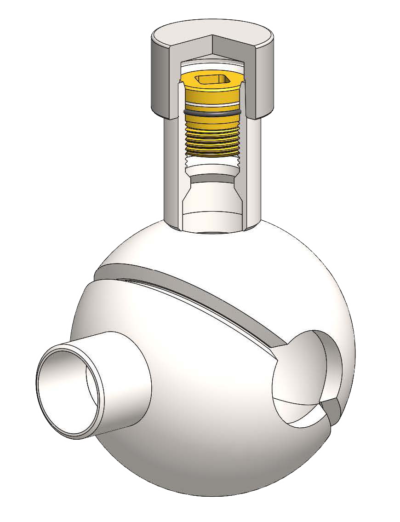

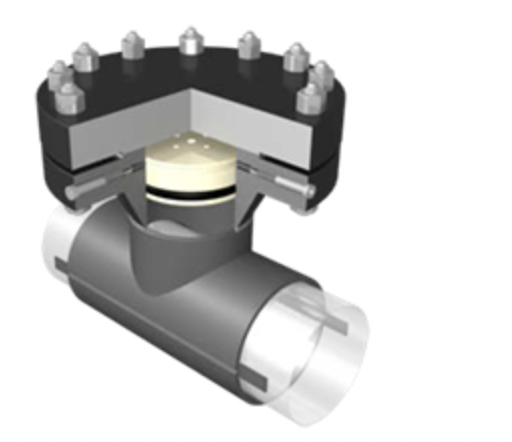

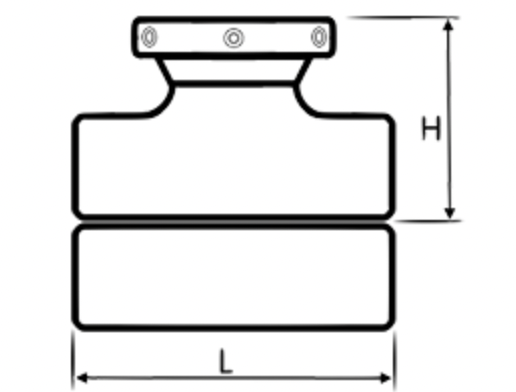

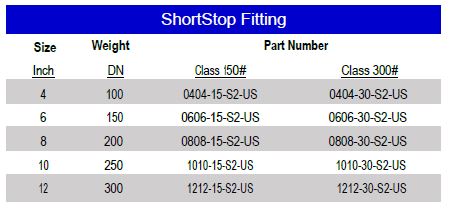

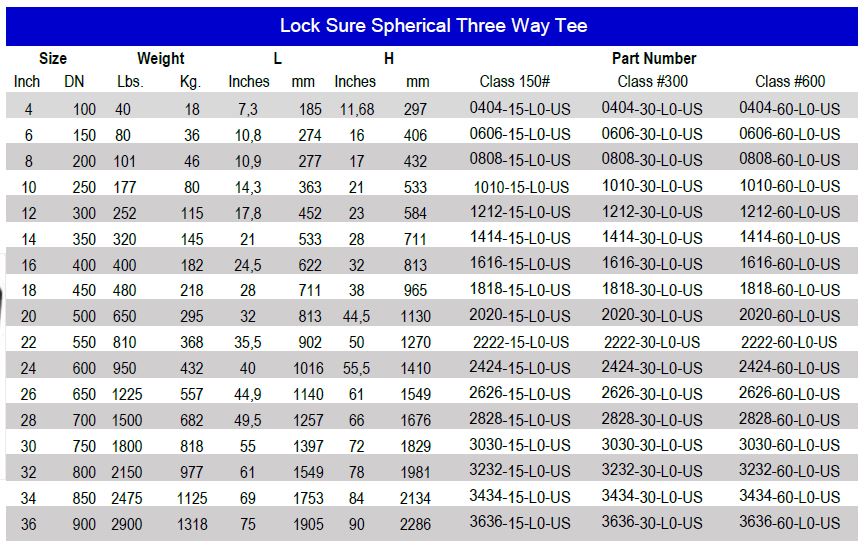

ANSI 150/300/600/900 Class Hot Tap & Line Stop Fittings

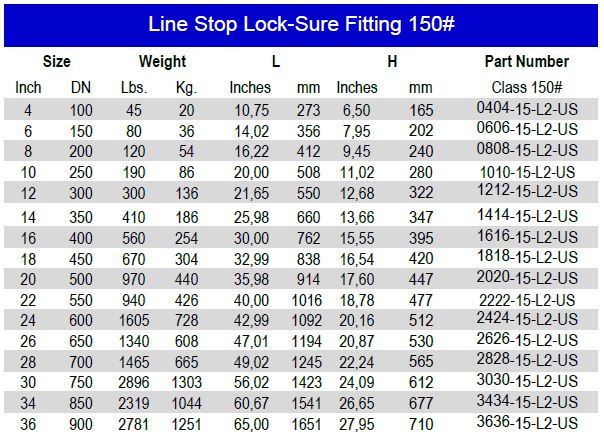

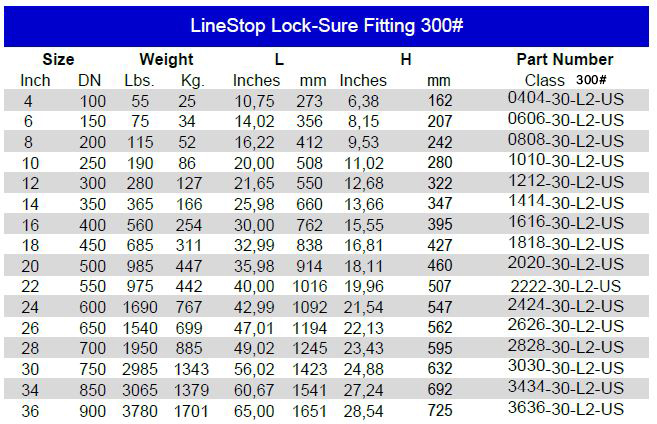

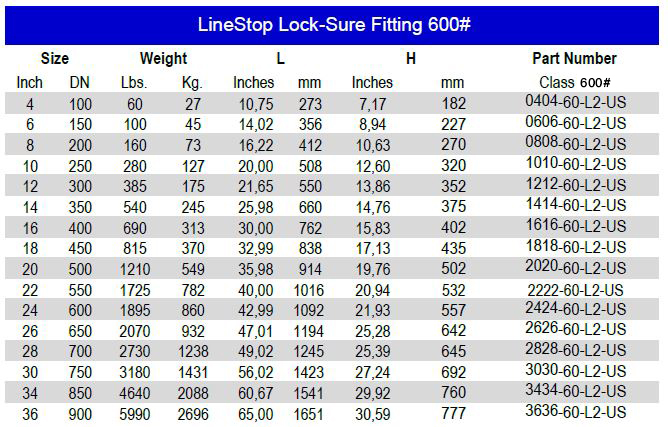

Inline’s Hot Tap & Line Stop Fittings are available in ANSI Class 150, 300, 600 or 900. Larger pressure ratings are available through our “Engineered to Order “ products. All fittings are available in compliance with applicable codes including ASME B31.3 and DOT “Buy American” compliant.

Hot Tap & Line Stop Fitting Specifications

Design Data:

• Design Codes: ASME B31.8/4, B31.1, B31.3

• Design Pressure: 150# Class – 900# Class

• Design Factor: 0.4, 0.5, 0.6, 0.72

Materials:

• Plate: A860 All Grades – A516 GR 70 or A537 CI.1

• Flanges: ASTM A105 Ø ≤ 24” ASME B16;5 Ø > 24” MSS-SP-44/ASME B16.47.; A350 GR. LF2 CI.1

• Bolts & Nuts: ASTM A193 B7/194 2H

• Pipe: API 5L Gr.B, ASTM A106 Gr.B, A333 GR.6

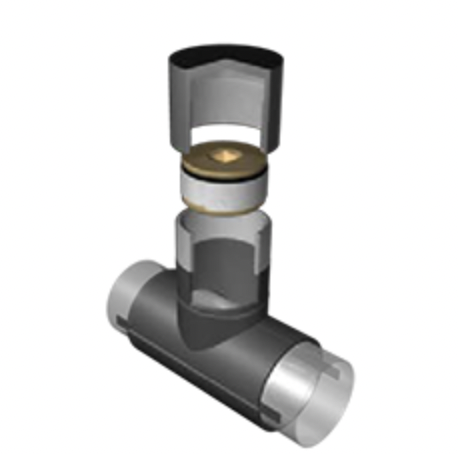

Key Features:

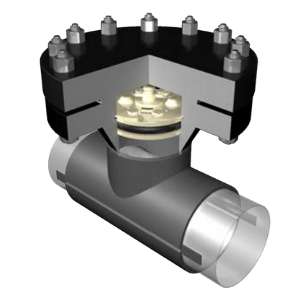

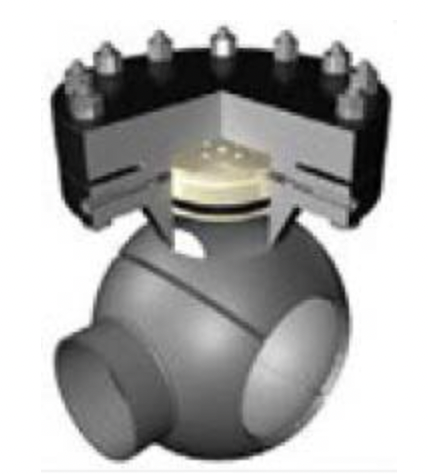

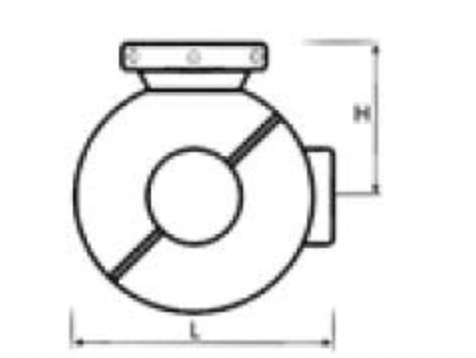

• Lock Sure Flange Secures Completion Plug

• Allows Tapping Valve to be removed after job is complete

• Lock Sure Flow Though Pig Guide Bars

• Extruded/Engineered Sleeves

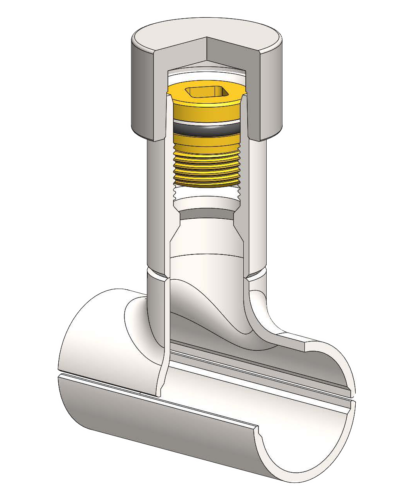

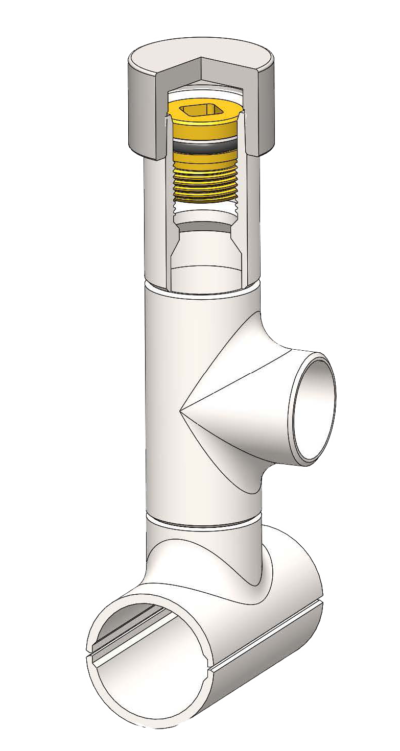

Key Features:

• Allows fitting to be installed in low grade areas

• Allows Product to flow while Hot Tapping and Line Stop though permanent bypass

• Lock-Sure Plug with Pig Guide Bars

• Designed for Fully Rated pipeline systems

5256 Brittmoore Rd, Houston, TX 77041 | Main Office 832-324-1518 | sales@inlineps.com